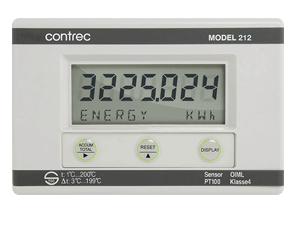

Energy Monitoring

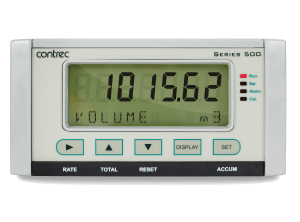

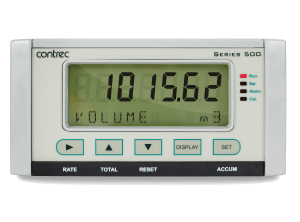

Contrec 515 – HC01

Heat Calculator - Frequency Flow (Volume)

Contrec 515 – HC01

Heat Calculator - Frequency Flow (Volume)

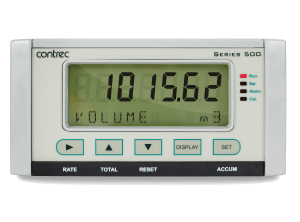

Contrec 515 – HC02

Heat Calculator - Analogue Flow (Volume)

Contrec 515 – HC02

Heat Calculator - Analogue Flow (Volume)

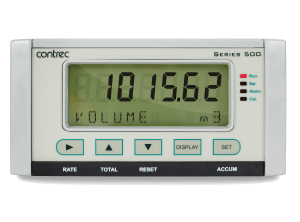

Contrec 515 – HC03

Heat Calculator - DP Meter (Mass Span)

Contrec 515 – HC03

Heat Calculator - DP Meter (Mass Span)

Contrec 515 – HC04

Heat Calculator for stacked DP meters (ISO 5167 and V-Cones)

Contrec 515 – HC04

Heat Calculator for stacked DP meters (ISO 5167 and V-Cones)

Contrec 515 – HC06

Heat Calculator - DP Meter (Volumetric Span)

Contrec 515 – HC06

Heat Calculator - DP Meter (Volumetric Span)

Contrec 515 – HC12

Heat Calculator - Analogue Flow (Mass)

Contrec 515 – HC12

Heat Calculator - Analogue Flow (Mass)

Energy Monitoring

The need for accurate energy monitoring in industrial applications has become paramount. Today, the cost of utilities is one of the biggest overheads a company will have to budget for, if this energy is not monitored and controlled properly businesses can find themselves with huge bills for wasted energy. Gas, steam, compressed air, hot and chilled water are all extremely expensive to produce and so there is an ever increasing need for accurate energy monitoring, after all “you can’t manage what you can’t measure”.

Flow measurement plays a pivotal role not just in monitoring the flow of liquids and gases to maximise production processes, but it is increasingly being used as a tool for analysing and forecasting potential maintenance issues on plant equipment such as pumps, valves, filters. It is also essential tool for manufacturers of steam boilers and air compressors to allow them to justify efficiency and therefore offer cost savings which can be achieved by switching suppliers. The areas where energy monitoring is used is endless but below are several examples where Contrec energy products have been installed:

• Steam and condensate metering on boiler systems

• Natural gas distribution on regional networks

• Compressed air monitoring

• Hot water energy in district heating systems

• General gas (Nitrogen, Argon, Carbon Dioxide, Oxygen) measurement

• Power Generation installations

• Biogas production in waste/water industries

• Chilled water energy for building temperature control

For more information on Contrec solutions for energy monitoring call us on +44 1422 829944 or email us at [email protected]