Contrec 515 – SC03

Steam Flow Computer

Steam Flow Computer

The 515 SC03 application measures the volume, mass and energy content of steam by using single or stacked differential pressure mass

flow inputs in conjunction with a temperature and/or pressure input. A selection of various modes makes it suitable for many steam applications. The instrument calculates the flow according to generic differential pressure equations and incorporates the conditions at which the flowmeter was calibrated. The instrument calculates the mass flow and energy according to the IAPWS Industrial Formulation (1997)

for the thermodynamic properties of steam. The equations use the pressure and temperature values to determine the specific volume and

the specific enthalpy. A specific enthalpy adjustment can be used to offset any initial energy.

Calculations

The steam energy calculations are based on the IAPWS Industrial Formulation (1997).

Superheated steam regions are:

0°C < t < 800°C

32°F < t < 1472°F

P < 100 MPa

P < 14500 psia

800°C < t < 2000°C

1472°F < t < 3632°F

P < 10 MPa

P < 1450 psia

Saturated steam regions are:

0°C < t < 374°C (critical temperature)

32°F < t < 705°F

P < 22 MPa (critical pressure)

P < 3190 psia

Water region is:

0°C < t < tsaturation at system pressure

32°F < t < tsaturation at system pressure

Formulas

Volume flow = Mass flow x Specific volume

Energy flow = Mass flow x Net SE

Net SE = SE – SEadj (if SE > SEadj otherwise 0)

(SE = Specific Enthalpy

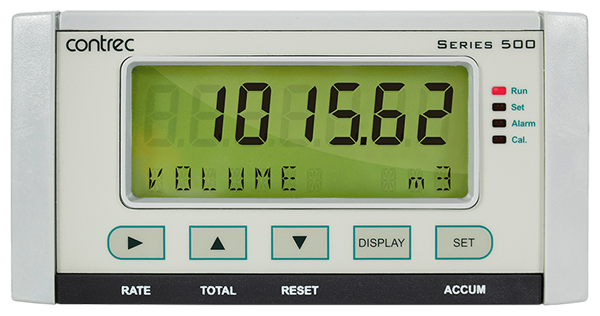

Displayed Information

The front panel display shows the current values of the input variables and the results of the calculations. A list of the variables for this application and their type (total or rate) is shown at the end of this document.

The instrument can be supplied with a real-time clock for data logging of over 1000 entries of the variables as displayed on the main menu.

Communications

There are two communication ports available as follows:

• COM-1 RS-232 port

• COM-2 RS-485 port (optional) or Ethernet (optional)

All types of ports can be used for remote data reading, while RS-232 and RS-485 serial ports can be used for printouts and for uploading and downloading of the application software to the instrument.

Isolated Outputs

The opto-isolated outputs can re-transmit any main menu variable. The type of output is determined by the nature of the assigned variable. Totals are output as pulses and rates are output as 4-20 mA signals. One output is standard, a second output is available as an option.

Relay Outputs

The relay alarms can be assigned to any of the main menu variables of a rate type. The alarms can be fully configured including hysteresis. Two relays are standard with two additional relays available as an option.

Software Configuration

The instrument can be programmed to suit the particular application needs and the flexible I/O can be assigned as required. Program settings can be changed either via the front panel (depending on assigned access levels) or via the 500 Series Program Manager (500-PM software).

The instrument stores all set-up parameters, totals and logged data in non-volatile memory with at least 30 years retention.